If you haven’t already read the first part of this Self-balancing robot series, I would encourage you to do so now! The first section below deals with a little bit of theory behind the sensors, so if you want to get straight to the programming/building part, please feel free to skip to the second section…

Deciding which Gyroscope Module to Use

So you have decided to go ahead with the project and construct your own self-balancing robot? That’s great! Now we can start by looking at one of the most significant elements of this project; the sensor. Traditionally the sensor of preference for stabilisation is a gyroscope. Now-days gyroscopes are extremely small and very cheap to buy, so they are ideal for amateur electronics projects. Unfortunately these gyroscopes (both the cheap and the not-so-cheap versions) also come with their own problems. They are good for short-term and quick movements, but tend to drift over time as the error accumulates. They also record a lot of jitter and noise, which needs to be filtered by the micro-controller before the data can be used.

To reduce this drifting effect of the gyroscope, it is possible to combine the sensor data with that from an accelerometer. The accelerometer is good at sensing slower and more prolonged movements, rather than the fast motion. Therefore if we take the best of both worlds and fuse the data together, we will be left with an extremely accurate picture of the motion of the robot.

As a result I decided to use a combined accelerometer & gyroscope breakout module (the MPU-6050), which is slightly more expensive than a simple gyro, but should lead to a superior stabilisation performance. Note: the MPU-6050 comes with a library which does all of the sensor fusion calculations for you, so that definitely is a plus!

Getting started with the Accel-Gyro Module

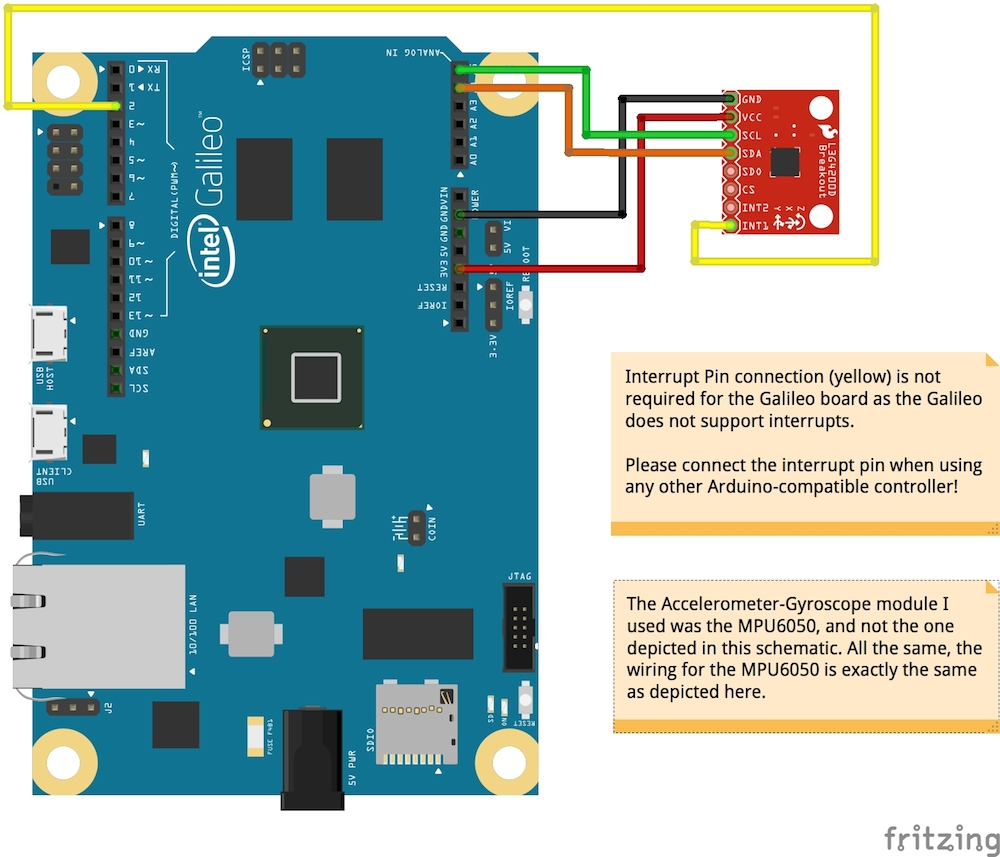

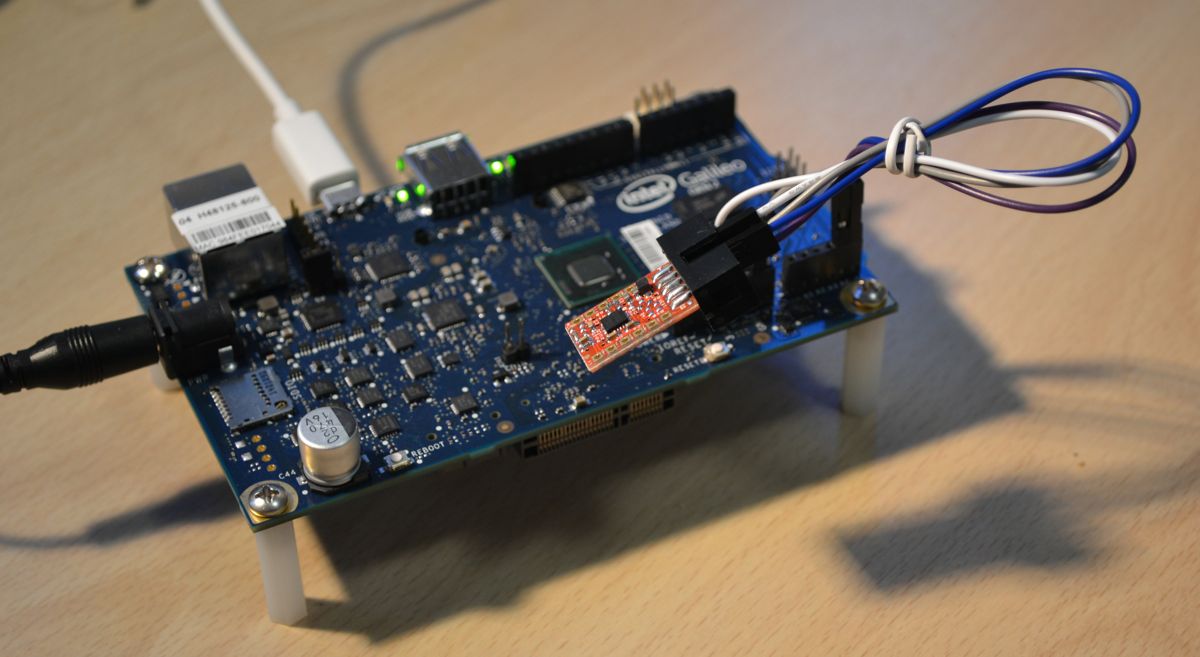

The MPU-6050 uses I2C to communicate with the micro-controller, so I started by connecting up the pins as shown in the schematics: the SDA line connects to the Analog pin 4, the SCL to Analog pin 5, power input to the 3.3v pin and the ground to the GND pin. If you are using one of the newer Arduinos, you could also connect the sensor to the dedicated SDA and SCL header pins.

As I am using an Intel Galileo Gen2 board, I did not use the interrupt pin. In general it is very bad practice to disregard the interrupts, as it might cause the buffer holding the sensor data to overflow, but for some reason the Galileo does not support normal interrupts! In order to get the sensor working correctly on the Galileo Board, I spent a lot of time on getting the timing right so that there is no overflow of incoming sensor data.For all other Arduino-compatible board, you should use the interrupt so that the micro-controller deals with new sensor data the moment that it is sent. (The interrupt pin is connected to Arduino digital pin 2)

Now it is time to get some data from the accel-gyro module! To do this I simply used the sample code which came with the documentation of the MPU6050 in order to read the raw sensor data. For this sample to work, the I2Cdev and the MPU6050 libraries need to be installed. Here is the code:

// I2C device class (I2Cdev) demonstration Arduino sketch for MPU6050 class

// 10/7/2011 by Jeff Rowberg <jeff@rowberg.net>

/* ============================================

I2Cdev device library code is placed under the MIT license

Copyright (c) 2011 Jeff Rowberg

Permission is hereby granted, free of charge, to any person obtaining a copy

of this software and associated documentation files (the "Software"), to deal

in the Software without restriction, including without limitation the rights

to use, copy, modify, merge, publish, distribute, sublicense, and/or sell

copies of the Software, and to permit persons to whom the Software is

furnished to do so, subject to the following conditions:

The above copyright notice and this permission notice shall be included in

all copies or substantial portions of the Software.

THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE

AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER

LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM,

OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN

THE SOFTWARE.

===============================================

*/

// I2Cdev and MPU6050 must be installed as libraries, or else the .cpp/.h files

// for both classes must be in the include path of your project

#include "I2Cdev.h"

#include "MPU6050.h"

// Arduino Wire library is required if I2Cdev I2CDEV_ARDUINO_WIRE implementation

// is used in I2Cdev.h

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include "Wire.h"

#endif

// class default I2C address is 0x68

// specific I2C addresses may be passed as a parameter here

// AD0 low = 0x68 (default for InvenSense evaluation board)

// AD0 high = 0x69

MPU6050 accelgyro;

//MPU6050 accelgyro(0x69); // <-- use for AD0 high

int16_t ax, ay, az;

int16_t gx, gy, gz;

#define LED_PIN 13

bool blinkState = false;

void setup() {

// join I2C bus (I2Cdev library doesn't do this automatically)

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

// initialize serial communication

// it's really up to you depending on your project)

Serial.begin(115200);

// initialize device

Serial.println("Initializing I2C devices...");

accelgyro.initialize();

// verify connection

Serial.println("Testing device connections...");

Serial.print("MPU Connection ");

Serial.println(accelgyro.testConnection() ? "successful" : "failed");

// configure Arduino LED

pinMode(LED_PIN, OUTPUT);

}

void loop() {

// read raw accel/gyro measurements from device

accelgyro.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

// display tab-separated accel/gyro x/y/z values

Serial.print("a/g:\t");

Serial.print(ax); Serial.print("\t");

Serial.print(ay); Serial.print("\t");

Serial.print(az); Serial.print("\t");

Serial.print(gx); Serial.print("\t");

Serial.print(gy); Serial.print("\t");

Serial.println(gz);

// blink LED to indicate activity

blinkState = !blinkState;

digitalWrite(LED_PIN, blinkState);

}The result I got on the Serial Monitor looked like this:

Initializing I2C devices...

Testing device connections...

MPU Connection successful

a/g: -1428 14240 12120 -536 131 -149

a/g: -1416 14196 11972 -505 110 -169

a/g: -1484 14260 11948 -524 108 -147

a/g: -1508 14220 11968 -513 87 -151

a/g: -1540 14176 11920 -501 15 -164

a/g: -1408 14212 11984 -523 27 -153

a/g: -1472 14104 11888 -526 123 -137

a/g: -1400 14236 11936 -514 136 -148

a/g: -1512 14216 12008 -522 132 -142

a/g: -1412 14172 11956 -520 127 -158

a/g: -1456 14120 11936 -533 94 -166

a/g: -1496 14124 11936 -529 97 -161

a/g: -1496 14208 11996 -526 108 -177

a/g: -1420 14236 11992 -505 104 -151

a/g: -1540 14264 11984 -510 115 -171

a/g: -1468 14300 12068 -504 51 -143

a/g: -1508 14172 11868 -545 105 -137

a/g: -1416 14244 11812 -523 69 -154

a/g: -1472 14276 11956 -504 92 -146

a/g: -1492 14192 12028 -517 143 -175In this data we can see the readings from the accelerometer already divided into the x/y/z values, and the readings from the gyroscope are also divided into its x/y/z components. This is a great first step, but unfortunately this data is not very usable in its current form. We still have to fuse the accelerometer and gyroscope data together, and then filter it to remove all of the noise!

Manipulating the data

It is possible to calculate the tilt of the sensor manually through the use of a number of formulas, but fortunately (at least for the MPU-6050) there is a library to do this for us! As a matter of fact, the MPU-6050 has a built-in “Motion Processing Unit” (hence the initials) which can be used to process the sensor data, therefore minimising the load on the micro-processor. This library also automatically filters the data so that we get a clean and usable result straight away.

Above is the equation used to calculate the angle of inclination from the accelerometer data, where (Ax) and (Ay) are the x- and y- accelerometer values. If you want to find out about calculating the angles manually, please visit: http://www.kerrywong.com/2012/03/08/a-self-balancing-robot-i/. Kerry Wong does an awesome job at describing the whole system, so I would encourage you to check it out! He covers all of the main topics such as the calculations, sensor fusion and the Kalman filter.

As regards the filtering, here is another great post which looks at the main advantages and disadvantages of using the a complimentary filter instead of the MPU6050 motion-apps library: http://www.geekmomprojects.com/mpu-6050-redux-dmp-data-fusion-vs-complementary-filter/

Updated: 23rd May 2019 – Reformatted post